Biosolids

myhreBiosolids Management

Overview:

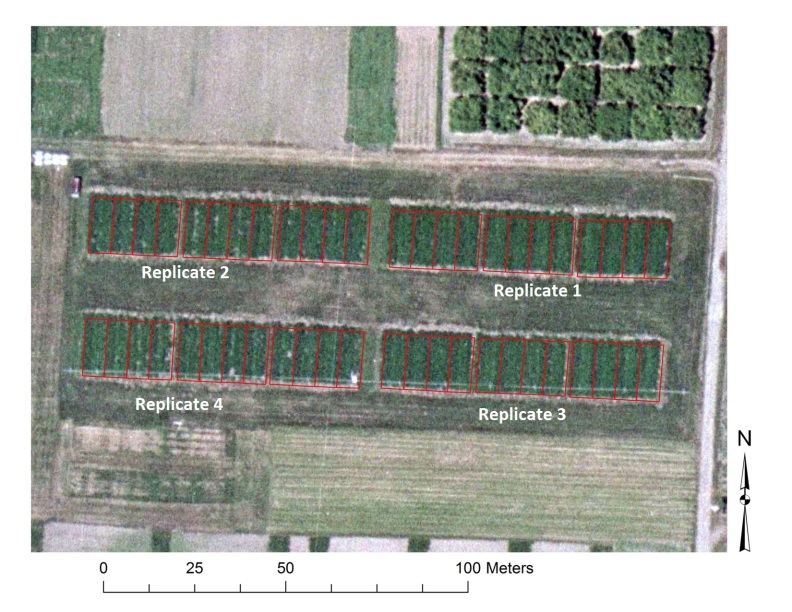

Biosolids are stabilized solids from municipal wastewater treatment that meet federal criteria for land application. They are a good source of plant nutrients (particularly nitrogen, phosphorus, sulfur, and zinc). We have done research on nutrient availability from biosolids in dryland wheat rotations in eastern Washington and irrigated forage grasses in western Washington. We also have a biosolids and compost demonstration garden at WSU Puyallup. We have been partners in a national biosolids study designed to develop simple methods to predict the availability of nitrogen from different types of biosolids in different environments, and in a study assessing the fate of flame retardants in biosolids.

♣ Worksheet for Calculating Biosolids Application in Agriculture (PDF-Online, complete publication, revised Jan 2021) or ♣ Download Worksheet (Excel XLS-Online). Sullivan, D.M., D. Griffin LaHue, B. Dari, A.I. Bary, and C.G. Cogger. 2021. PNW0511. Pacific Northwest Extension Publication.

Links:

♣ Oregon State University Department of Crop & Soil Science, biosolids resources.

♣ Northwest Biosolids Management Association, information, events, message board.

♣ Washington State Department of Ecology Biosolids Program, information, regulations, permitting, reports, FAQs.

♣ US Environment Protection Agency Office of Wastewater Management, FAQs, regulations, publications

Slideshows:

♣ Soils and Biosolids Nutrient Management (PDF-Online, 74 slides, use browser vertical scroll bar to page through slides), presented at Clackamas short course.

♣ Soil Carbon Sequestration Potential in Urban Soils (PDF-Online, 19 slides, use browser vertical scroll bar to page through slides).

Publications – Extension and Management Bulletins:

♣ Worksheet for Calculating Biosolids Application in Agriculture (PDF-Online, complete publication, revised Jan 2021) or or ♣ Download Worksheet (Excel XLS-Online). Sullivan, D.M., D. Griffin LaHue, B. Dari, A.I. Bary, and C.G. Cogger. 2021. PNW0511. Pacific Northwest Extension Publication.

♣ Fertilizing with Biosolids (PDF-Online). Sullivan, D.M., C.G. Cogger, and A.I. Bary. 2015. PNW 508. Pacific Northwest Extension Publication.

♣ Gardening and the Use of Biosolids are listed on our Gardening Page.

♣ Biosolids in Dryland Cropping Systems (PDF-Online). Sullivan, D.M., C.G. Cogger, A.I. Bary, and L.J. Brewer. 2018. PNW 716. Pacific Northwest Extension Publication.

♣ Biosolids Management Guidelines for Washington State (PDF-Online). Cogger, C.G., D.M. Sullivan, C.L. Henry, and K. P. Dorsey. 2000. Washington State Dept. Ecology Pub. #93-80.

♣ Urban Highway Roadside Soils and Shrub Plantings are Enhanced by Surface Applied and Incorporated Organic Amendments (Request pdf e-copy). Bary. A. R.L. Hummel, and C. Cogger. 2016. J. Arbor. Urban Hort. 42:418-427.

♣ Fate of Antibiotics and Antibiotic Resistance During Digestion and Composting: A Review (Request pdf e-copy). Youngquist, C.P, S.M. Mitchell, and C.G. Cogger. 2016. J. Environ. Qual. 45:537-545. doi:10.2134/jeq2015.05.0256

♣ Antibiotic Degradation During Thermophilic Composting (Request pdf e-copy). Mitchell, S.M., J.L. Ullman, A. Bary, C.G. Cogger, A.L. Teel, and R.J. Watts. 2015. Water Air Soil Pollut. 226:13.

Publications – Other Reports:

♣ A Survey of Skagit County Residents: Opinions about Local Reuse and Recycling of Biosolids Compost (Full Report, PDF-Online) or ♣ Online Summary (PDF-Online). Youngquist, C. P. and J. R. Goldberger. Washington State University. 2013. As part of a Washington State University (WSU) research project funded by the Town of La Conner, WA, a mail survey of Skagit County residents was conducted in 2013. The objectives were (1) to gain a better understanding of residents’ attitudes, opinions, and knowledge about the use of “Class A” biosolids on agricultural land and in the community; and (2) to explore potential correlations between attitudes about biosolids and the demographics and lifestyle choices of respondents. The results provide valuable insight into Skagit County residents’ attitudes, opinions, and knowledge about local waste management, local agricultural use of “Class A” biosolids, and the use of biosolids-based fertilizers on food crops. This information will be useful to local governments, community groups, waste management personnel, farmers, and researchers.

Publications – Peer-reviewed Journals:

♣ Marigold and Pepper Growth in Container Substrates Made from Biosolids Composted with Carbon-Rich Organic Wastes (Request pdf e-copy). Hummel, R.L., C. Cogger, A. Bary, and R. Riley. 2014. HortTechnology 24:325-333.

♣ Biosolids Applications to Tall Fescue Have Long-Term Influence on Soil Nitrogen, Carbon, and Phosphorus (Request pdf e-copy). Cogger, C.G., A.I. Bary, E.A. Myhre, and A.M. Fortuna. 2013. J. Environ. Qual. 42:516–522.

♣ Long-Term Crop and Soil Response to Biosolids Applications in Dryland Wheat (Request pdf e-copy). Cogger, C. G., A. I. Bary, A. C. Kennedy, and A.M. Fortuna. 2013. J. Environ. Qual. 42:1872-1880.

♣ Estimating Nitrogen Availability of Heat-Dried Biosolids (Request pdf e-copy). Cogger, C.G., A.I. Bary, and E.A. Myhre. 2011. Applied Environ. Soil Sci. Vol. 2011, Article ID 190731, 7p. doi:10.1155/2011/190731

♣ Dryland Winter Wheat Yield, Grain Protein, and Soil Nitrogen Responses to Fertilizer and Biosolids Applications (Request pdf e-copy). Koenig, R.T., C.G. Cogger, and A.I. Bary. 2011. Applied Environ. Soil Sci. Vol. 2011, Article ID 925462, 9p. doi:10.1155/2011/925462.

♣ Quantifying Benefits Associated with Land Application of Residuals in Washington State (Request pdf e-copy). Brown, S. K. Kurtz, A. Bary, and C. Cogger. 2011. Env. Sci. Tech. 45:7451-7458.

♣ Chrysanthemum Production in Composted and Noncomposted Organic Waste Substrates Fertilized with Nitrogen at Two Rates Using Surface and Subirrigation (Request pdf e-copy). Krucker, M., R.L. Hummel, and C. Cogger. 2010. HortSci. 45:1695-1701.

♣ Predicting Biosolids Application Rates for Dryland Wheat Across a Range of Northwest Climate Zones (Request pdf e-copy). Sullivan, D., Bary, A., Cogger, C. and Shearin, T. 2009. Commun. Soil Sci. Plant Anal. 40:1770-1789.

♣ Biosolids Recycling: Nitrogen Management and Soil Ecology (Request pdf e-copy). Cogger, C.G., T.A. Forge, and G.H. Neilsen, 2006. Can. J. Soil Sci. 86:613-620.

♣ Biosolids Processing Effects on First and Second Year Available N (Request pdf e-copy). Cogger, C.G., Bary, A.I., D.M. Sullivan, and E.A. Myhre. 2004. Soil Sci. Soc. Am. J. 68:162-167.

♣ Decomposition and Plant-Available Nitrogen in Biosolids: Laboratory Studies, Field Studies, and Computer Simulation). (Request pdf e-copy). Gilmour, J.T., C.G. Cogger, L.W. Jacobs, G.K. Evanylo, and D.M. Sullivan. 2003. J. Environ. Qual. 32:1498-1507.

♣ Seven Years of Biosolids vs. Inorganic Nitrogen Applications to Tall Fescue (Request pdf e-copy). Cogger, C.G., A.I Bary, S.C. Fransen, and D.M. Sullivan. 2001. J. Environ. Qual. 30:2188-2194.

♣ Nitrogen Recovery from Heat-Dried and Dewatered Biosolids Applied to Forage Grasses (Request pdf e-copy). Cogger, C.G., D.M. Sullivan, A.I. Bary, and S.C. Fransen. 1999. J. Environ. Qual. 28:754-759.

♣ Matching Plant-Available Nitrogen from Biosolids with Dryland Wheat Needs (PDF-Online). Cogger, C.G., D.M. Sullivan, A.I. Bary, and J.A. Kropf. 1998. J. Prod. Agric. 11:41-47.

♣ Biosolids and Dairy Manure as Nitrogen Sources for Prairiegrass on a Poorly Drained Soil (Request pdf e-copy). Sullivan, D.M., S.C. Fransen, C.G. Cogger, and A.I. Bary. 1997. J. Prod. Agric. 10:589-596.